The 3-D Revolution

It’s the stuff of sci-fi movies, futuristic novels and fantasy stories. The possibility of printing real objects—objects that you can touch and feel and hold—has always seemed more of a dream than reality. However now, that’s no longer the case. 3-D printing has become a reality through human advancements in technology and will change the world in ways no one could ever foresee.

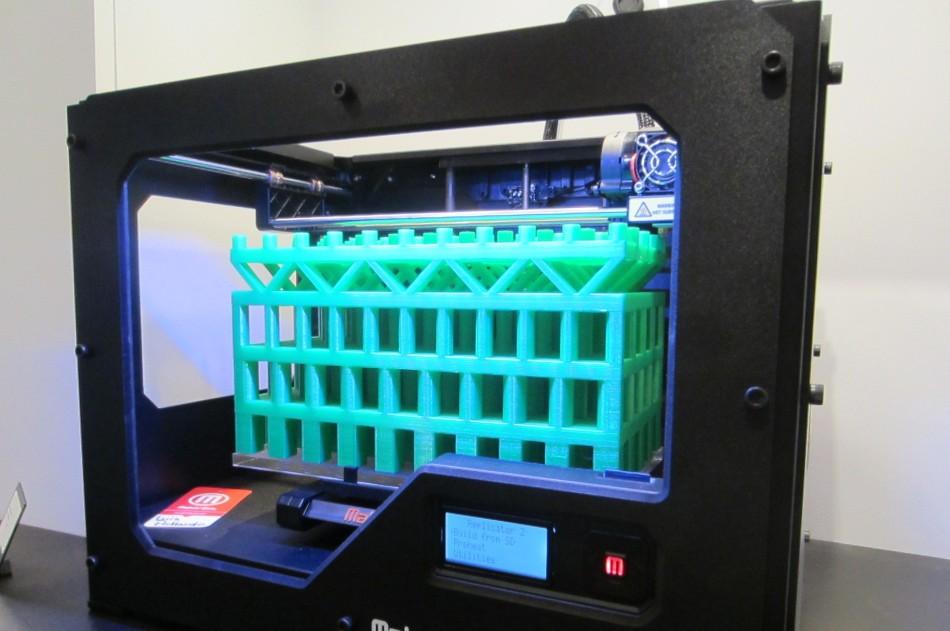

Additive manufacturing, a family of manufacturing technology, was the real driving force behind 3-D printing. Like stalagmites and stalactites formed in caves through dripping water forming layers and layers of mineral deposits over thousands of years, additive manufacturing creates objects by layering material until it gradually forms into the desired shape. All you need to know when printing, though, is how to create your object digitally, hit print and consider your object built. It’s really as simple as that.

Large industries are increasingly relying on 3-D printers to make parts and prototypes. Smaller innovative companies use 3-D printers to customize and tailor products to meet the customers’ needs. For example, Bespoke Prosthetics in San Francisco, Calif. uses 3-D printing to create coverings for artificial limbs. With just a few changes in computer code, the company can design a unique covering for every person, according to UD Director of Technology Michael Speer.

So what exactly makes 3-D printing so much easier and better than just simply building the products the way we’ve been doing it for centuries? For one, goods can be customized in an infinite number of ways. Altering products won’t require a complete design overhaul. Instead, changing little instructions in the software can create a whole different kind of product tailored specifically to meet a customers’ needs. 3-D printing also eliminates the cost of shipping fees. Rather than having products made in just a few factories and paying expensive fees to get them distributed around the world, it’s now possible for products to be made in-store in every metropolitan area, according to the Harvard Business Review. As Speer says, “3-D has staggering potential to change the world. For many years computers allowed people with little training to produce polished publications and make their own music and movies. 3-D printing will allow people with very little training to make their own stuff.”

For between $1,375 to $2,899, you can order your very own 3-D printer from makerbot.com. We’ve entered the age of 3-D, and it’s time for everyone to be a part of this revolution.

Jennifer is a senior at Berkeley and has served on Fanfare as a staff writer, a news section editor, the social media editor, and now the co-editor-in-chief....